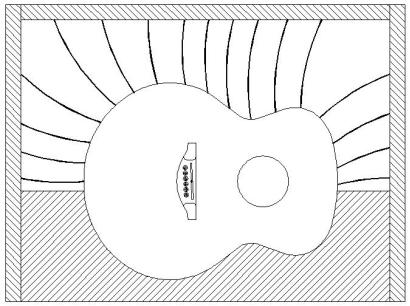

Well I thought I would get cute and make a new way of clamping binding in place during glue up. I built a half box near guitar shaped fixture to rig go-bar type clamping in the horizontal plane to secure binding in place. The opposite edge indexed to a near half a mold. The Idea was to do half an edge at a time. I bought a bunch of 3/32 hickory rod and cut them to a short length for this experiment. All went well till I got to the upper bout and I let a rod slip and it went through the side. I may be able to repair the side but I will not sell this one. Sorry no pics as Diane still has not got Micki Sue to send back our camera. But here is a drawing of the idea Me thinks it needs refining

(emoticon used as blid as a bat)

(emoticon used as blid as a bat)

got that t-shirt too

got that t-shirt too